The Black Art

Procedural Control (a.k.a. non-radar)

The Bedrock of ATC: If you don't understand non-radar, you don't understand Air Traffic Control.

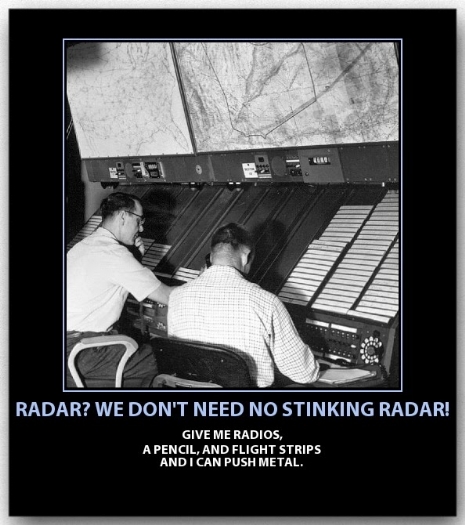

Procedural control is a method of providing air traffic control services without the use of radar. Using procedural control, the controller must maintain a mental picture of the location of aircraft based on each aircraft's flight progress strip, which contains its route, altitude and estimated times over reporting points. That information is compared against all other aircraft in the sector to determine if there are any conflicts. This is not a trivial task and requires the single most important trait of an Air Traffic Controller: spatial visualization.

For aircraft that conflict, the controller issues an altitude, speed or routing change that both separates the conflicting aircraft from each other, while still remaining separated from all others. After all conflicts have been resolved in this way, the sector is considered "separated" and the controller only needs to check again for conflicts when new aircraft are added, or if an aircraft needs to change its altitude, or if the aircraft reaches a reporting point significantly earlier or later than previously estimated.

The fix posting area method was the main technique used. This method evolved from similar techniques used in railroad dispatch. It simplifies conflict detection because aircraft on different routes can only possibly conflict at intersection points with other routes, or with aircraft on the same route. Each intersection point ("fix posting area") in the sector is made into a separate bay on the strip rack, and multiple strips are printed for each aircraft, one per bay.

The controller then sorts strips within each bay by the estimated time the aircraft is expected over that point. Only aircraft estimated to cross within 10 minutes of each other (oversimplification) are considered possible conflicts, at which point altitudes are then compared to determine if there actually is a conflict. Aircraft on the same route, however, (in either direction) must be checked for conflict regardless of time over the intersection. As new altitudes are issued, all of the strips for that aircraft must be annotated with the new data and separation checked again at all of the intersections it passes through.

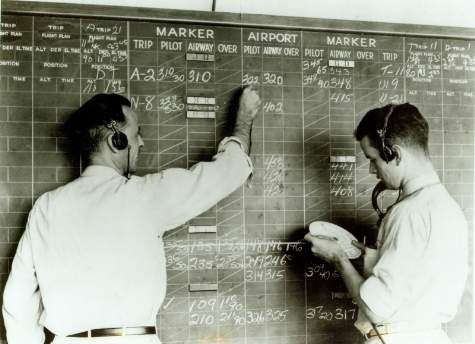

In the early years, Air Traffic Control (ATC) was a primitive science. The tools of ATC were a blackboard, a large table map, a Teletype machine, and a telephone.

To track aircraft, controllers posted incoming flight information on a large blackboard, which could be revised as they received new reports on takeoffs, en route progress, and landings. They transferred the blackboard information to a large table map that depicted all airways converging on the area they monitored.

Reliance was placed on a radio operator, miles away, relaying reports from pilot to Center controllers. Pilot reports and estimates were the only source of information available to the controller to pinpoint the locations of flights under his control jurisdiction. It was a time consuming and airspace wasting operation; however, with few aircraft at relatively slow speeds this system was satisfactory.

Note the circular slide rule, a.k.a. "Whiz Wheel". A very necessary tool in this environment.

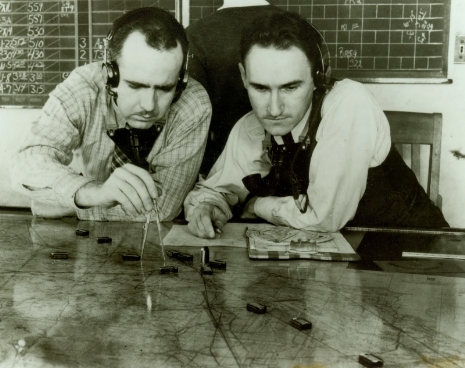

Controllers placed small brass markers, shaped like shrimp boats, on the face of the map. Each marker represented a flight in the station’s control area. The shrimp boat indicated the position of an aircraft, with the flight’s identity, time of departure, and altitude.

The controller moved the markers every fifteen minutes to indicate visually the estimated progress of the aircraft. By looking at the shrimp boats on the map, a controller could see the traffic along the routes he controlled and detect potential conflicts.

In a non-radar environment, controllers cannot "see" where the aircraft is. They must base their separation decisions on pilot position reports.

Note the "Whiz Wheel" on the clipboard.

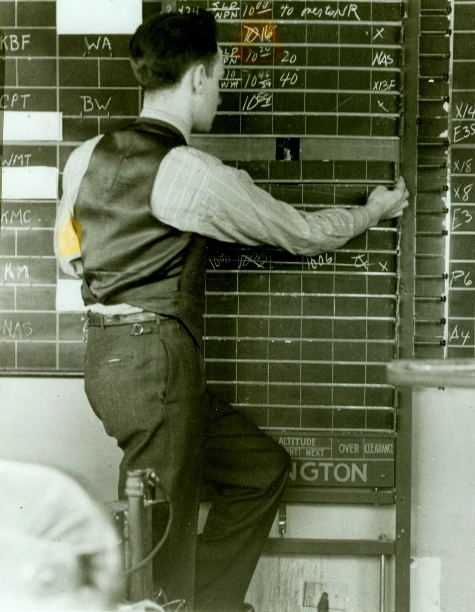

To avoid the need to erase and rewrite revisions, some bright individual got the idea of sawing the blackboard into slats that could be arranged as required to show the air traffic picture.

In 1938, this simple idea prompted John Huber of the Washington Center to design the first Flight Progress Board using paper strips. He brought it into Washington Center and said, "I have built this holder. You guys figure out how to use it!" Up until that time, all efforts had been aimed at improving the blackboard, which had not really improved the system or made it easier to keep track of aircraft.

Thanks to Ken Kerr for providing the information on how it was done in the 50s'

The Salt Lake ARTCC was officially commissioned on April 1, 1939, as part of the Civil Aeronautics Authority. The first operating space was located below the tower on the third floor of the Municipal Airport Administration Building (terminal).

Space totaled approximately 300 square feet. Control of the entire center area was from one sector. At the time the Center was commissioned, there were only nine other Centers in the United States and only two others (Los Angeles and Oakland) west of the Mississippi.

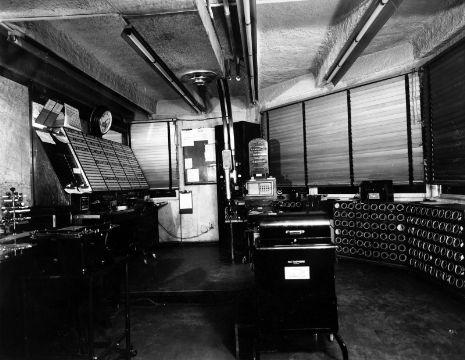

Question: What are all the circular slots used for?

See below for answer.

The flight progress strips became an invaluable tool in helping controllers perform their separation duties. Through the use of standardized procedures and markings, trained controllers could use these strips to visualize the relative position of every aircraft and apply the proper separation procedures.

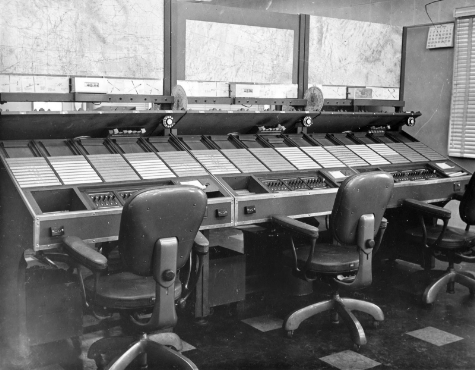

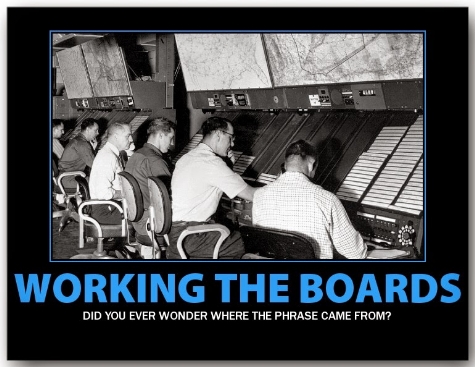

The control boards had a front and back. The front was where the controllers sat and controlled traffic. There were strips similar to the modern strips that are used in today’s environment but they were all hand produced. Even the times were figured by the assistant controller who was located behind the boards.

In March 1957, operations space was doubled and seven sectors were activated.

Whenever the controller issued an instruction to a pilot or the pilot made a position or altitude report, the controller wrote the information on the flight progress strip. The strip could then be readily interpreted to determine the status of the aircraft. This information aided the controller in visualizing the position of each aircraft and made it much easier for other controllers to evaluate the airspace.

On December 3, 1957, the jet routes were designated, and four high altitude sectors were added to make a total of 11 sectors.

The flight progress strip also became a valuable record of the instructions issued by the controller and any reports made by the pilot, in case of an investigation following an incident or an accident. It was the controller’s responsibility to constantly update the information contained on the flight progress strip to be able to visualize both the present and, more important, the future position of every aircraft being separated.

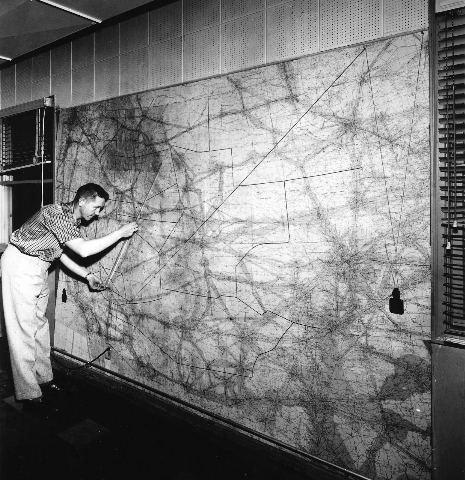

Except for those aircraft that were on designated airways; e.g. Green 6, Red 49, Amber 2 etc. all direct flights which were basically all military, had to be plotted for routing, distance between check points and of course strips prepared for each airway crossing point.

To plot these routes we had a large board on the “A” (assistants) side with a string attached. With this string we would plot the aircraft's route -- and through this method, arrive at the number of strips needed, and calculate the times between each check point. Most military flight plans were sent to us in coordinates.

Some of these flight plans would take as much as 30 to 40 minutes to plot.

Flight Data feverishly processing flight plans manually. They were dropped in the correct bay, above the header, from behind the control position.

There was a space between the back boards and the front where the assistant would drop the strips down in the proper bay. The controller at the front, would place the strips in the proper bay, sequenced by time.

To figure the times between check points, a circular slide rule was used. Each controller had one at his control position and would have to recalculate an aircraft's speed at each check point and of course pass this info on to the next controller.

I want to reiterate that all the strips were manually prepared and at the proper time based on the aircraft entering our system.

Flight Data generally required more staff than the control positions. Processing

a flight plan was a manually intensive procedure. The Flight Data

section would receive the information, calculate the distances between

the fixes in the flight plan, factor in the speed and figure out the

time it would take the airplane to travel the distance. They would

hand-write the strips for each sector and deliver them to the control

positions.

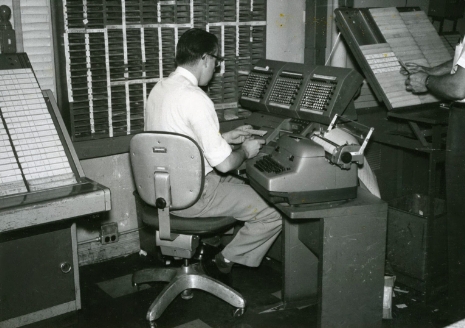

1961 ZLC IBM 858 Cardatype Machine

IBM 858 Cardatype machine. This system was actually a programmable accounting machine, which would print flight progress strips and make simple calculations as to the estimated time over a fix. From this simple beginning, began the era of automation for air traffic control. Programmed with a plug board and wires.

There is little information on how this system was used or how it was programmed for route of flight. If you used this system, please send us your recollections.

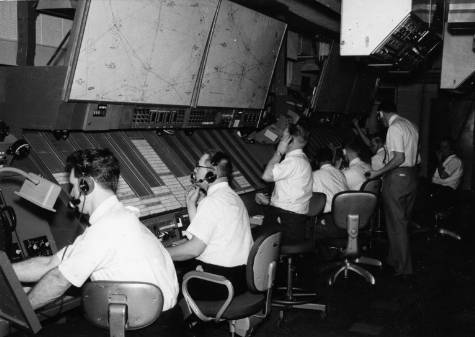

1961 ZLC High Sectors

Answer to 1941 ZLC. The circular slots are used to store the wax cylinders for the Dictaphone machine. A precursor to magnetic tape, the wax cylinders were used for recording the telephones and playing back a low quality but audible sound.

Each cylinder could be reused 100-120 times by putting them in a machine that erased them by shaving off the surface.

Perhaps this dapper gentleman is investigating an incident or performing a tape talk, or in this case, a cylinder talk.

Final Thoughts

Flight strips have been used for almost 80 years for strategic control of air traffic. The procedures for their use have evolved and have been validated by generations of controllers.

You could see the writing on the wall for the demise of flight strips. The AAS system was designed for glass strips (emulated on a monitor) but turned out to be a catastrophic failure. The DSR system was a scaled down version and curved strip bays were tacked on to the displays in a very unergonomic fashion.

Flight strips have gone the way of the lighted airways and shrimp boats. They have become obsolete, replaced by an automated system: the User Request Evaluation Tool (URET). The system electronically displays the same flight management information as paper flight progress strips.

You could see the writing on the wall for the demise of flight strips. The AAS system was designed for glass strips (emulated on a monitor) but turned out to be a catastrophic failure. The DSR system was a scaled down version and curved strip bays were tacked on to the displays in a very unergonomic fashion.

Flight strips have gone the way of the lighted airways and shrimp boats. They have become obsolete, replaced by an automated system: the User Request Evaluation Tool (URET). The system electronically displays the same flight management information as paper flight progress strips.

The URET system is a conflict-detection tool that automatically detects and advises air traffic controllers of potential conflicts between aircraft or between aircraft and special activity airspace within the National Airspace System. The strategic planning tool allows controllers to create alternative, conflict-free flight routings and to manage changing air traffic or weather conditions.

The URET system is a conflict-detection tool that automatically detects and advises air traffic controllers of potential conflicts between aircraft or between aircraft and special activity airspace within the National Airspace System. The strategic planning tool allows controllers to create alternative, conflict-free flight routings and to manage changing air traffic or weather conditions.I worked with strips my entire career and would feel uncomfortable working without them. They were the last backup to a failure of the automation. Present systems still require the human to have a mental picture of all traffic and a mental model of the airspace. Controllers need to step in at any time should there be a computer failure. I wish the new generation luck if the systems crash.

Non-Radar Concepts Video

My time at the FAA academy was almost a half-century ago. Everyone in the class had difficulty with the non-radar problems. The instructors did a poor job of explaining how they were to be applied in an actual problem. Most of those who flunked out did so during this portion of the training.

Here is a link to a very lenthy description of how to apply manual (non-radar) procedures. I wish they had showed us something like this during my time at the academy.